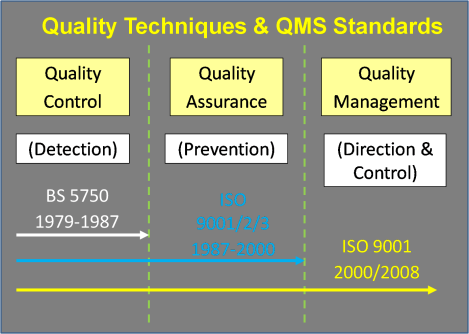

QA/QC is the combination of quality assurance, the process or set of processes used to measure and assure the quality of a product, and quality control, the process of meeting products and services to consumer expectations.

Quality assurance, or QA for short, refers to a program for the systematic monitoring and evaluation of the various aspects of a project, service, or facility to ensure that standards of quality are being met.

Quality control emphasizes testing of products to uncover defects, and reporting to management who make the decision to allow or deny the release, whereas quality assurance attempts to improve and stabilize production, and associated processes, to avoid, or at least minimize, issues that led to the defects in the first place.

Nondestructive testing or Non-destructive testing (NDT) is a wide group of analysis techniques used in science and industry to evaluate the properties of a material, component or system without causing damage.

The terms Nondestructive examination (NDE), Nondestructive inspection (NDI), and Nondestructive evaluation (NDE) are also commonly used to describe this technology.

Common NDT methods include ultrasonic, magnetic-particle, liquid penetrant, radiographic, remote visual inspection (RVI), eddy-current testing, and low coherence interferometry.

Terminology

- Qualified instructions on how to complete the weld.

- A WPS is a written (qualified) welding procedure prepared to provide direction for the making of production welds.

- Record of the welding parameters and test results

- A PQR is a record of welding data used to weld a test coupon

- Record of Welder test results and range of approval

Welding Inspector (WI) ?

- Inspect welds

Three basic work function categories:

- Overseer: code inspector

- Specialist: NDT radiographer

- Combination of overseer and specialist

WI – Essential Requirements:

- Physical Condition

- Attitude

- Knowledge of Welding

- Knowledge of Drawings, Specifications, and Procedures

- Knowledge of Testing Methods

- Records

- Education and Training

- Welding Experience

- Inspection Experience

- Certification of Qualification

Welding Inspection Operations

- Knowledge of drawings, standard/codes/specifications, and manufacturing instructions

- Verification of the manufacturer’r approved quality assurance program

- Verification of welder and inspector qualifications

- Verification of approved procedures for qualifying welders and inspection personnel

- Verification that approved welding and inspection procedures are being used

- Selection of production test samples

- Evaluation of test results

- Preparation of test reports and storage of records

- Safety

Typical Welding Inspection Procedure

- Material identification

- Chemical analysis

- Mechanical properties

- Edge preparation (including root face and beveling)

- Dimensions

- Cleanliness

- Root opening

- Tacking

- Backing (where required)

- Preheat and interpass temperatures

- Filler Metal

- Root Pass

- Root preparation prior to welding second side

- Cleaning between passes

- Appearance of passes

- In-process NDT inspection as required or specified

- Conformance to approved welding procedure

- Postheat treatment requirements

- Method of cleaning for inspection

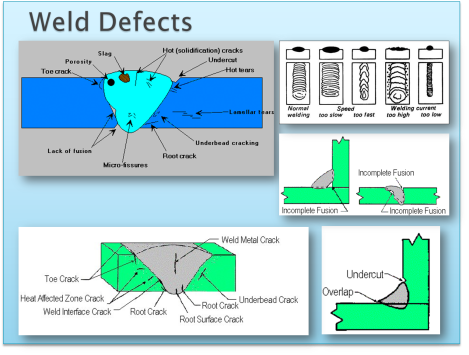

- Visual inspection

- Nondestructive testing (NDT)

- Destructive testing

- Repairs

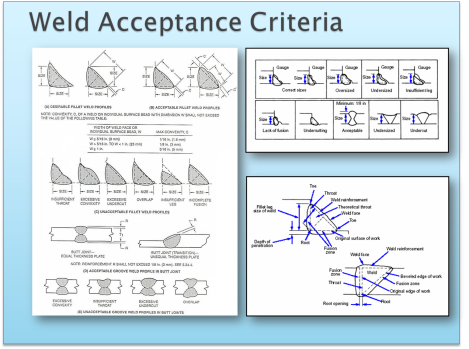

- Surface contour and finish of welds

- Conformity of welds with drawings

- Magnetic particle and liquid penetrant tests

- Radiography

- Ultrasonic tests

- Proof testing

- Other suitable methods

- Chemical

- Mechanical

- Metallographic

- An inspector should be able to maintain adequate records.

- To check all records for completeness and accuracy in accordance with specified requirements.

- To make certain that records are available when needed.

- Any records that require the fabricator’s signature should be prepared by the fabricator rather than the inspector.

- Records should be in as much detail as necessary.

- It is desirable that the inspector comment on th general character of the work, how well it stayed within prescribed tolerances, difficulties that occurred, and any defects.

- Any repair should be explained

- Copies of this records should go to all persons entitled to received them, and the inspector should keep a copy in his own file.

Uploaded in Youtube by darcyville on May 20, 2010

A 2 year program available at NSCC Pictou Campus.

- Category : Education

- License : Standard YouTube License

Related Links:

- CSWIP 3.0 – Visual Welding Inspector – Level 1 (http://www.twitraining.com/home/course-schedule/cswip-visual-welding-inspector-level-1)

References:

- QA/QC (http://en.wikipedia.org/wiki/QA/QC)

- QA (http://en.wikipedia.org/wiki/Quality_assurance)

- Nondestructive testing (http://en.wikipedia.org/wiki/Nondestructive_testing)

- NDT Videos – All the best NDT related videos from around the web (http://wiki.ndthub.com/ndt-videos)

- Welding Inspection & QC (http://wiki.ndthub.com/ndt-videos/32)

-

“Welding Inspection”, Second Edition, by AWS Committee on Methods of Inspection, American Welding Society, Miami, United States of America, 1980.

-

“Welding Procedure & Welder Qualification Review”, Bob Pennycook, Lloyd’s Register EMEA, http://www.lloydsregister.co.uk

-

“A Textbook of Welding Technology (For Engineering Students)”, 20th reprint, Dr. O.P. Khanna, YMCA Institute of Engineering, Faridabad, Haryana, Published by Ish Kapur for Dhanpat Rai Publications (P) Ltd, New Delhi, 2011

I want to say thank you for sharing your knowledge and your experience regarding metallurgy with us.

I really appriciate that you have shared with us great information about metallurgy.Thanks for sharing.

Its such as you read my thoughts! You seem to undedstand a lot

about this, like you wrote the book iin it or something.

I feel thqt you could do with a few percent too pressure the message houise a bit,

however other than that, this is magnificent blog. A fantastic read.

I’ll definitely be back.

I think the admin of this website is really working hard in favor of his site, as here every material is quality

based data.

Pingback: Homepage·

Pingback: cooking classes in Marietta·

Pingback: http://virtualsask.com/·

Pingback: slip and fall on ice settlements·

Pingback: goji vita·

Pingback: corporate portrait photography tips·

Pingback: Sound Hire Surrey·

Pingback: Cruz·

Pingback: phentermine·

Sweet blog! I found it while surfing around on Yahoo News.

Do you have any suggestions on how to get listed in Yahoo

News? I’ve been trying for a while but I never seem

to get there! Appreciate it

can I share the info in my personal page?

I will remark, credit back to your page

Yes, with my pleasure. thanks for visit my blog.

These are genuinely fantastic ideas in about blogging.

You have touched some nice factors here. Any way

keep up wrinting.

Great post. I was checking constantly this blog and I am impressed!

Extremely useful info specially the closing part :

) I care for such info much. I was looking for this particular information for a long time.

Thanks and good luck.

Great write-up, I am normal visitor of one’s website, maintain up the excellent operate, and It’s going to be a regular visitor for a lengthy time.

Hi , I need a rework procedure for co2 Welding , Will you able to share some details & Formats to my Mail ID-180592baskar@gmail.com

Check out some of my welding and inspection videos “Certified Welding Inspector” https://www.youtube.com/playlist?list=PLx4vVC-JkeaqXoBWCShRlhl32kXnPzd_w

Check out a few of my welding and inspection videos https://www.youtube.com/playlist?list=PLx4vVC-JkeaqXoBWCShRlhl32kXnPzd_w

Right away I am going to do my breakfast, once having my

breakfast coming over again to read additional news.

Nice Information for a new blogger……it is really helpful

Many Thanks!

This is the great piece of information, Thank you so much for sharing the tips are really helpful.

Great Information Thank you so much for sharing, also check the following links:

3PL company in India

Ecommerce Logistics Companies In India

Warehousing Services In Mumbai

Warehousing Facility In Mumbai