Introduction

The original kanji characters for this word are: 改 善

In Japanese this is pronounced “kaizen”.

- 改 (“kai”) means “change” or “the action to correct”.

- 善 (“zen”) means “good”.

The Japanese word “kaizen” means simply “improvement”.

This method became famous from Imai‘s 1986 book Kaizen: The Key to Japan’s Competitive Success.

Kaizen is a daily activity, the purpose of which goes beyond simple productivity improvement. It is also a process that, when done correctly, humanizes the workplace, eliminates overly hard work (“muri“), and teaches people how to perform experiments on their work using the scientific method and how to learn to spot and eliminate waste in business processes.

Kaizen is a system of continuous improvement in quality, technology, processes, company culture, productivity, safety and leadership.

Read more at: http://www.graphicproducts.com/tutorials/kaizen/#ixzz2ns6FyjgE

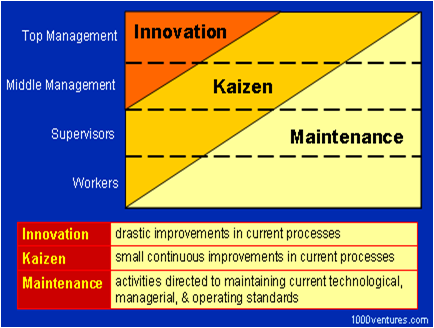

People at all levels of an organization can participate in Kaizen, from the CEO down, as well as external stakeholders when applicable.

The format for Kaizen can be individual, suggestion system, small group, or large group.

This group is often guided through the Kaizen process by a line supervisor; sometimes this is the line supervisor’s key role.

Key features of Kaizen

Key features of Kaizen include:

- Improvements are based on many, small changes rather than the radical changes that might arise from Research and Development

- As the ideas come from the workers themselves, they are less likely to be radically different, and therefore easier to implement

- Small improvements are less likely to require major capital investment than major process changes

- The ideas come from the talents of the existing workforce, as opposed to using research, consultants or equipment – any of which could be very expensive

- All employees should continually be seeking ways to improve their own performance

- It helps encourage workers to take ownership for their work, and can help reinforce team working, thereby improving worker motivation.

Implementation

The Toyota Production System is known for kaizen, where all line personnel are expected to stop their moving production line in case of any abnormality and, along with their supervisor, suggest an improvement to resolve the abnormality which may initiate a kaizen.

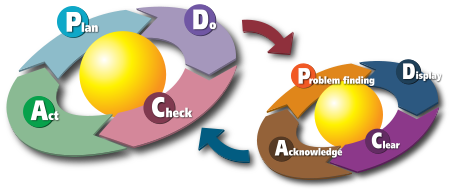

The cycle of kaizen activity can be defined as:

- Standardize an operation and activities.

- Measure the operation (find cycle time and amount of in-process inventory).

- Gauge measurements against requirements.

- Innovate to meet requirements and increase productivity.

- Standardize the new, improved operations.

- Continue cycle ad infinitum.

This is also known as the Shewhart cycle, Deming cycle, or PDCA.

Key elements of Kaizen are:

- Quality,

- effort,

- involvement of all employees,

- willingness to change and

- communication.

THE FIVE FOUNDATION ELEMENTS OF KAIZEN:

- Team work

- Personal Discipline

- Improved morale

- Quality circles

- Suggestions for improvement

OUT OF THIS FOUNDATION, THREE KEY FACTORS ARISE:

- Elimination of waste (muda) and incorporation of efficiency

- The Kaizen five – S framework for good housekeeping

- Standardization

The Kaizen five – S framework , for good housekeeping

- Seiri- tidiness

- Seiton- orderliness

- Seiso- cleanliness

- Seiketsu- standardized clean-up

- Shitsuke – discipline

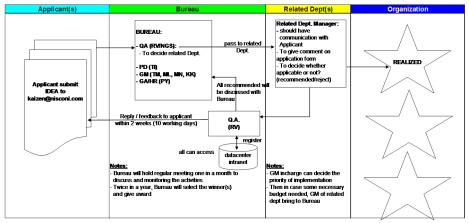

Kaizen Activities in EPCI Project

Herein, I would like to give an example how the Kaizen activities in EPCI project as done in NISCONI.

PT. Nippon Steel Construction Indonesia (PT NISCONI) was established on November 1st, 1972, with its head office in Jakarta, Indonesia as a joint venture company between Perusahan Pertambangan Minyak dan Gas Bumi Negara (PERTAMINA) and NIPPON STEEL CORPORATION, the world’s largest steel producer. In the year 1982, PT. Elnusa joined the company as one of the major partners.

With effective of 1st October 2012, Nippon Steel Corporation is merged with Sumitomo Metal Industries, Ltd and formed a new organization “NIPPON STEEL & SUMITOMO METAL CORPORATION”. Subsequently, effective from 1st January 2013, the name of PT. Nippon Steel Construction Indonesia is changed to PT. Nippon Steel & Sumikin Construction Indonesia (PT NISCONI).

PT. NISCONI offers comprehensive services in : Project Management, Engineering, Procurement, Fabrication, Construction, Transportation and Offshore Installation, Offshore Hook-up, Pre-commissioning, Commissioning / Start up for Lump Sum basis and also on reimbursable basis. NISCONI has successfull completed more than 30 major Oil & Gas Projects in Indonesia.

Flow Chart of Kaizen Activities in NISCONI

NISCONI KAIZEN BUREAU honors RAJ KAMAL & BERNANDA with the 2009 FIRST Kaizen PRIZE OF REALIZED

Following PT NISCONI KAIZEN activities from January 1st, 2009 till August 24th, 2009; we, PT NISCONI would like to express deepest gratitude for their employee contribution in this program.

“The Sand Container System” Kaizen Implementation Team was honored by NISCONI Kaizen Bureau with the 2009 First Kaizen Prize of Realized category. Bureau valued Bernanda’s team as best amongst 2 other Kaizen teams in realized category.

The Sand Container System (by Mr. Raj Kamal/ Bernanda & Team)

Before your Idea/Improvement:

North Belut WHP sand treatment processing is carrried out by Sand Handling System (SHS), originally designed for sand disposal to overboard by routing through disposal caisson. However prior to overboard disposal, the sand is tested to ensure the compliance with environmental standard of acceptable mercury content. If it is above the acceptable limit, treated sand is not allowed to be routed to disposal caisson.

Reason why you hit on the idea:

North Belut gas is expected to contain maximum 1200 ppbw of mercury. With this nature treated sand has considerably mercury content that would be not allowed for overboard disposal. Meanwhile expected sand production is 0.0227barrels/MMscf gas production, or 4.2 barrels/day with the design gas production rate. With this condition it is necessary to collect and transport sand to onshore for further processing as mercury removal processing is not available at the WHP.

Profit:

First experience project for Nisconi relevant to Sand Container System design, installation, and commissioning. It would be valuable for the future projects.

– Save the WHP overboard from mercury contamination

– Mercury removal system is not necessary to be installed in each WHP

References:

- Kaizen http://en.wikipedia.org/wiki/Kaizen)

- Continual improvement process (http://en.wikipedia.org/wiki/Continual_improvement_process)

- What is Kaizen? (http://www.graphicproducts.com/tutorials/kaizen/)

- NISCONI Kaizen Activities Procedure

Related articles

- What is Kaizen? What are the benefits of Kaizen? What do you need to do to get started using Kaizen principles? (apparelscience.wordpress.com)

- 5s (frederickromero37.wordpress.com)

- Kaizen (Continuous Improvement) (journeyofatrader.wordpress.com)

- The Kaizen Principle (jeremydbruce.wordpress.com)

- The Shewhart Cycle (business.answers.com)

- Kaizen- the art of continous improvement (laywi4us.wordpress.com)

It’s amazing to visit this site and reading the views of all friends about

this piece of writing, while I am also keen of getting know-how.

Hi there to all, how is all, I think every one is getting more from this web site,

and your views are pleasant for new visitors.

I know this web site offers quality based articles and extra information,

is there any other site which gives these kinds of data in quality?

I read this piece of writing completely about the resemblance of

hottest and earlier technologies, it’s awesome article.

We are a group of volunteers and starting a new scheme in our community.

Your website offered us with valuable info to work on. You’ve done an impressive job

and our whole community will be thankful to you.

Awesome article.

Kеep thiѕ goin please, great job!

Unquestionably imagine that which you stated. Your favourite

reason seemed to be on the internet the simplest factor to be aware of.

I say to you, I certainly get irked even as people think about issues that they just don’t recognize about.

You controlled to hit the nail upon the top as smartly as outlined out the entire thing with no

need side-effects , other people can take a signal. Will probably be back

to get more. Thanks

Hey There. I found your weblog using msn. This is an extremely smartly written article.

I’ll make sure to bookmark it and come back to read extra of your

useful info. Thank you for the post. I’ll definitely return.

At this moment I am ready to do my breakfast, when having my breakfast coming again to read further news.

This article will assist the internet people for setting

up new website or even a blog from start to end.

you are truly a excellent webmaster. The site loading speed is amazing.

It seems that you are doing any distinctive trick. In addition, The contents arre masterwork.

you have doe a excellent activity in this topic!

I savour, cause I discovered just what I

was having a look for. You’ve ended my four day lengthy hunt!

God Bless you man. Have a great day. Bye

I’m really inspired together with your writing skills and

also with the format in your weblog. Is this a paid theme or did you customize it

yourself? Either way keep up the excellent qualty writing, it’s

uncommon to peer a nice weblog like this one today..

Hello every one, here every person iis sharing such familiarity, thus

it’s fastidious to read this webpage, and I used

to pay a quick visit his weblog every day.

I have been browsing online more than three hours today, yet I never

found any interesting article like yours. It’s pretty

worth enough for me. Personally, if all website owners and bloggers made good content as you did,

the web will be much more useful than ever before.

I’m really inspired with your writing talents as neatly as with the layout on your weblog. Is that this a paid subject or did you modify it your self? Either way keep up the excellent quality writing, it is uncommon to peer a nice weblog like this one these days..